Operations & Maintenance (O&M) Management Services

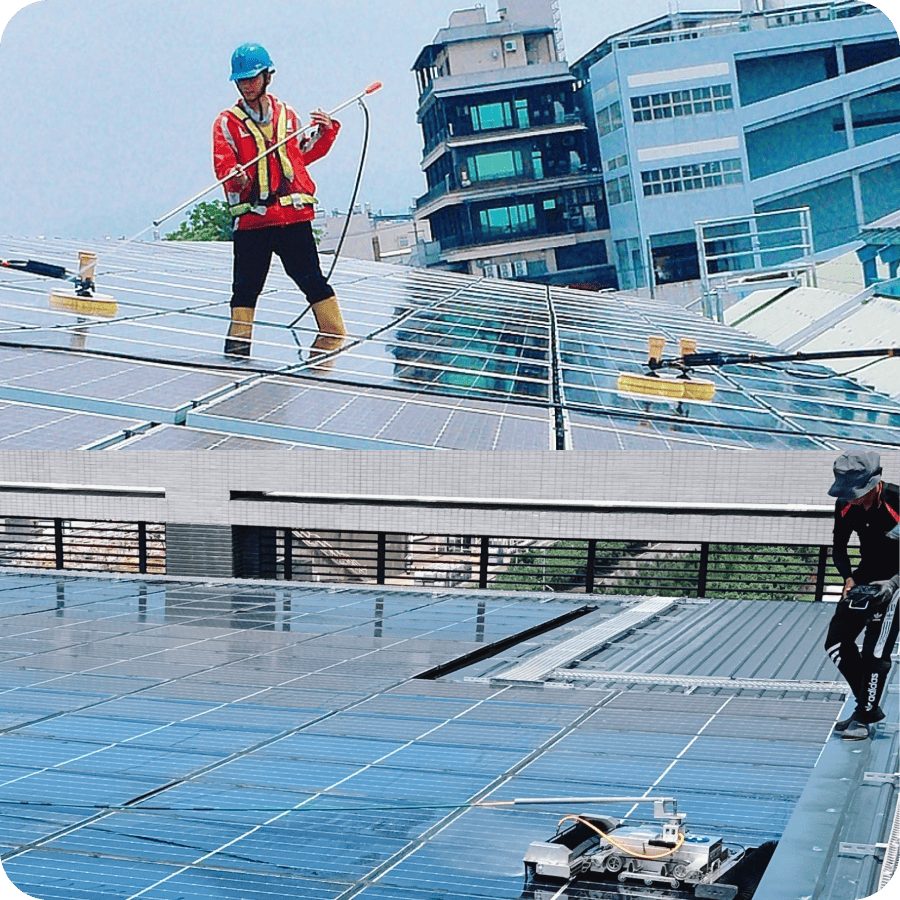

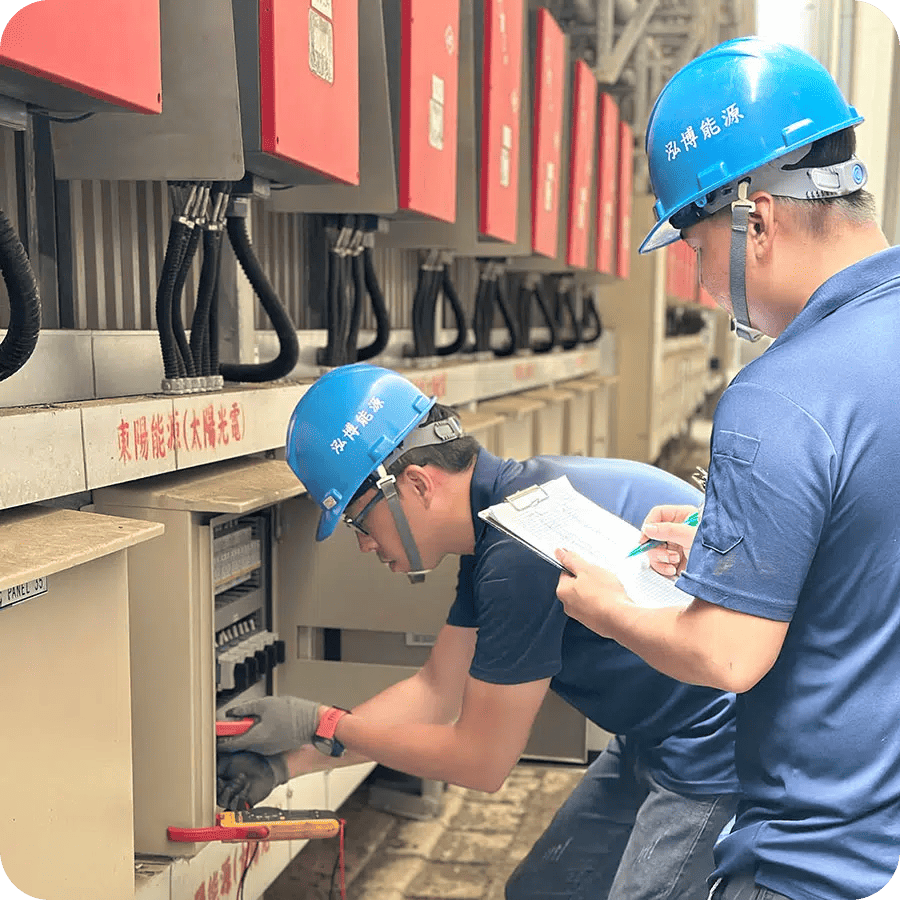

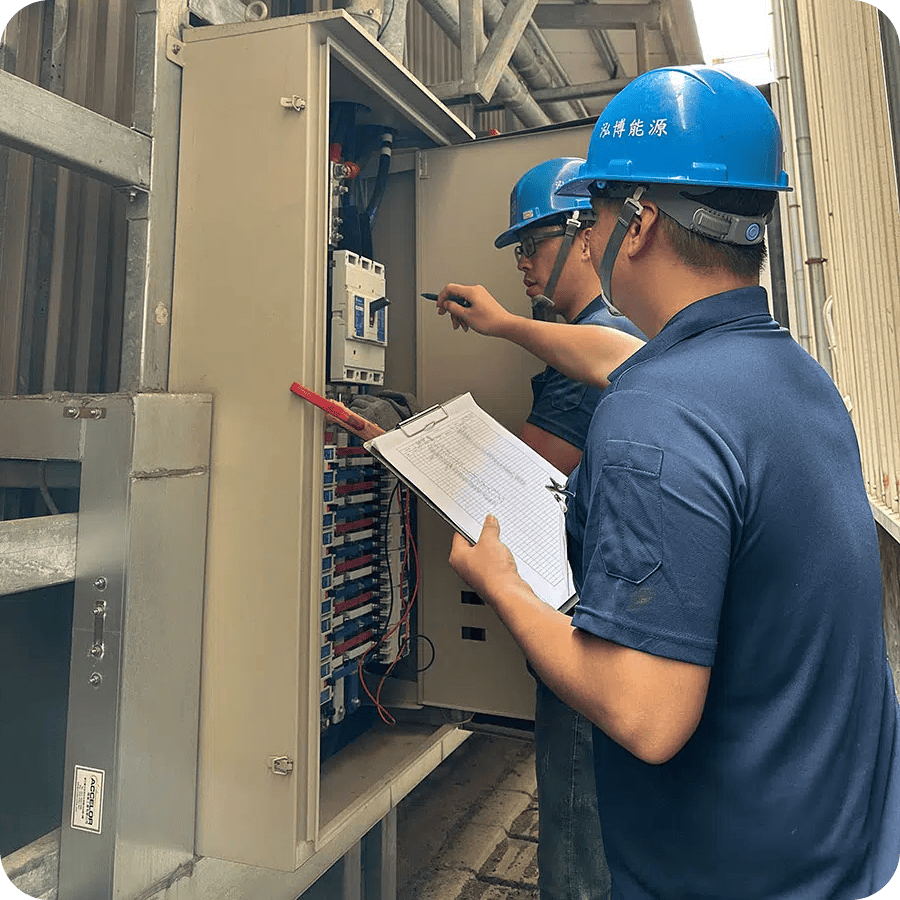

Preventive Maintenance and Cleaning

Through scheduled inspections and cleaning, equipment service life is extended. Services include:

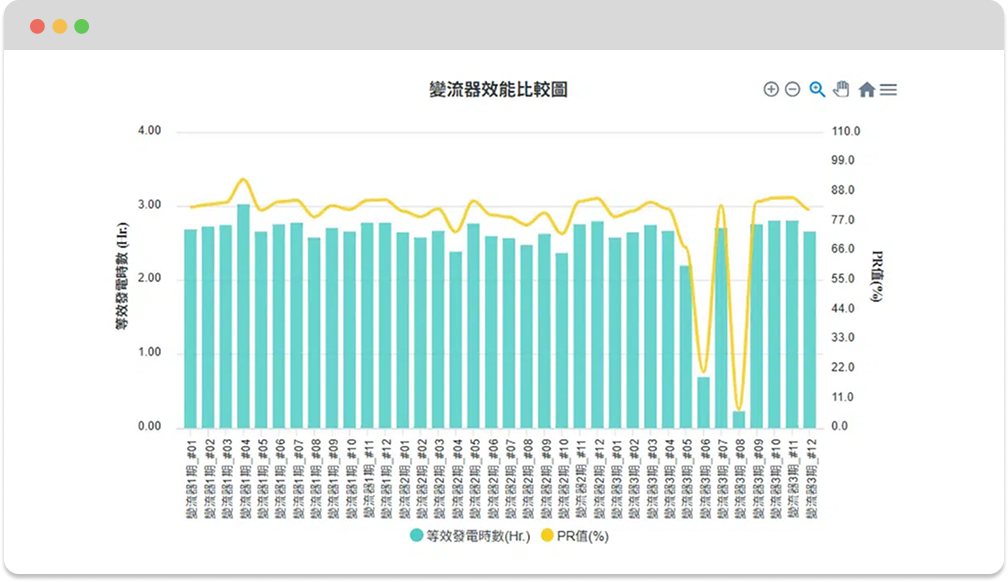

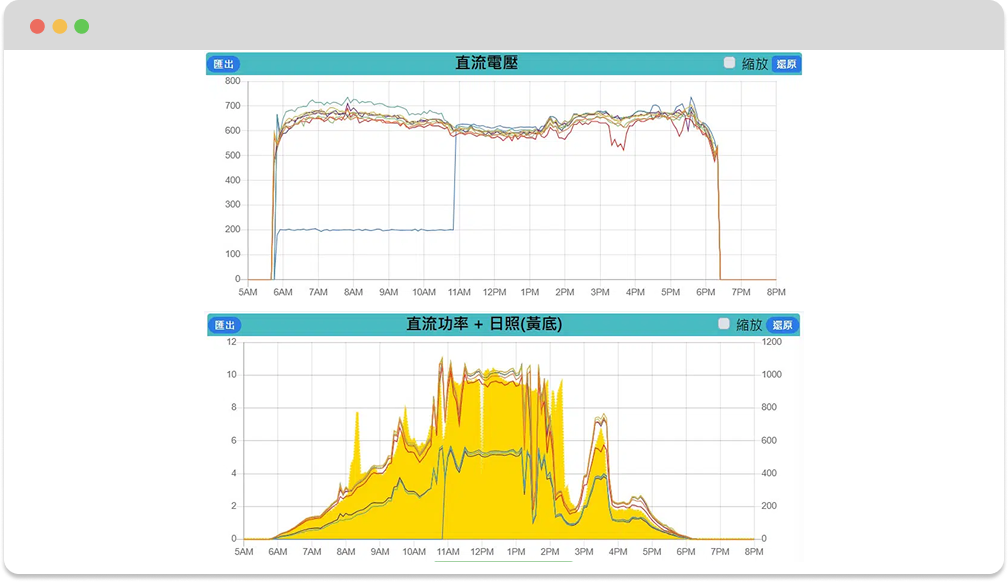

Real Time Remote Monitoring

The monitoring system continuously collects multiple data sources, including weather, environmental conditions, visual imagery, and power generation data. By integrating IoT data with intelligent algorithms, the platform provides proactive alerts, advanced analytics, and optimized task scheduling.

1. O&M Real Time Overview Dashboard

2. Automated IoT Data Analysis

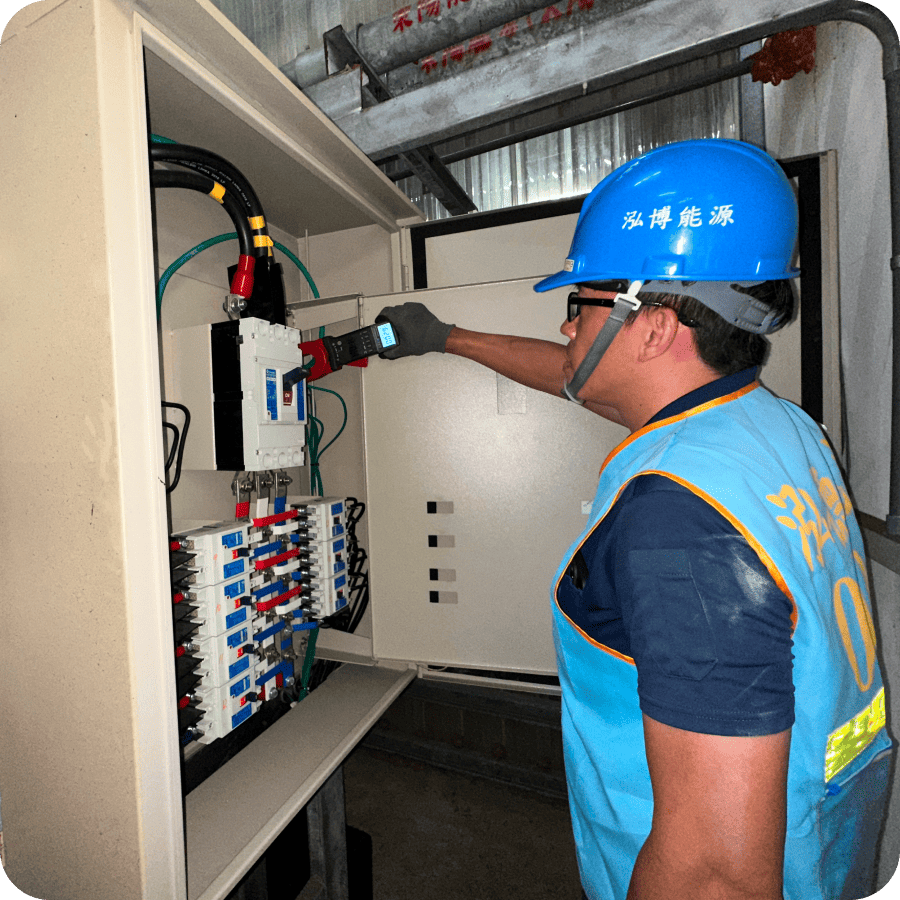

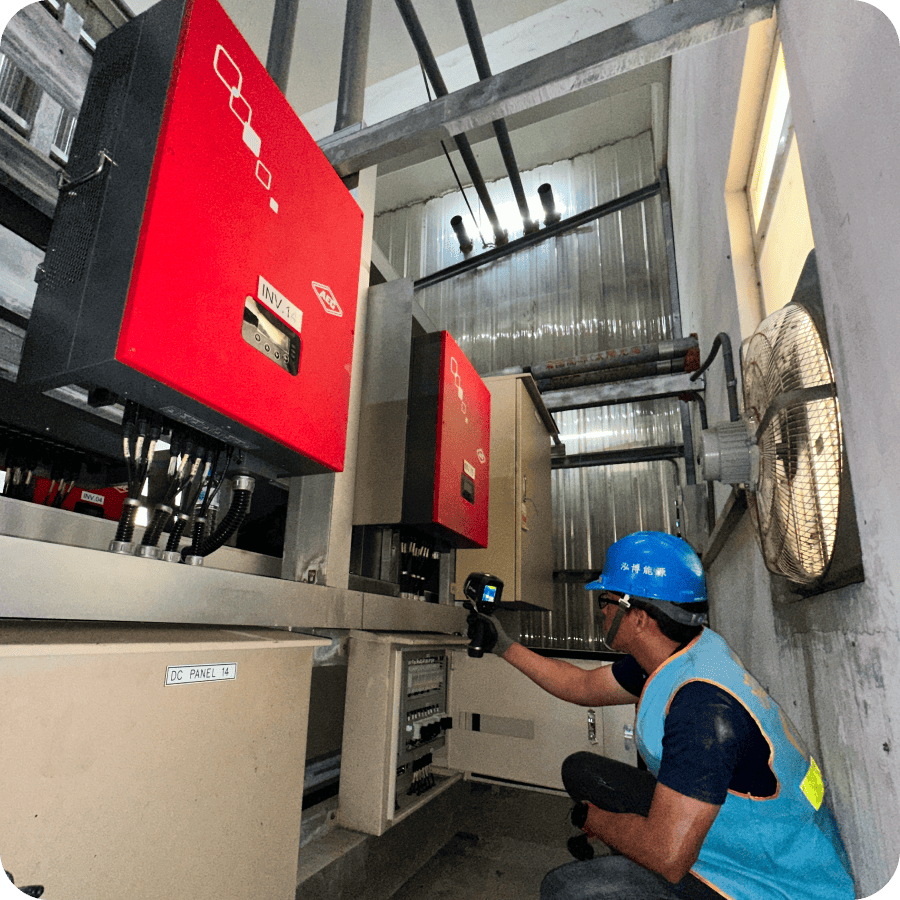

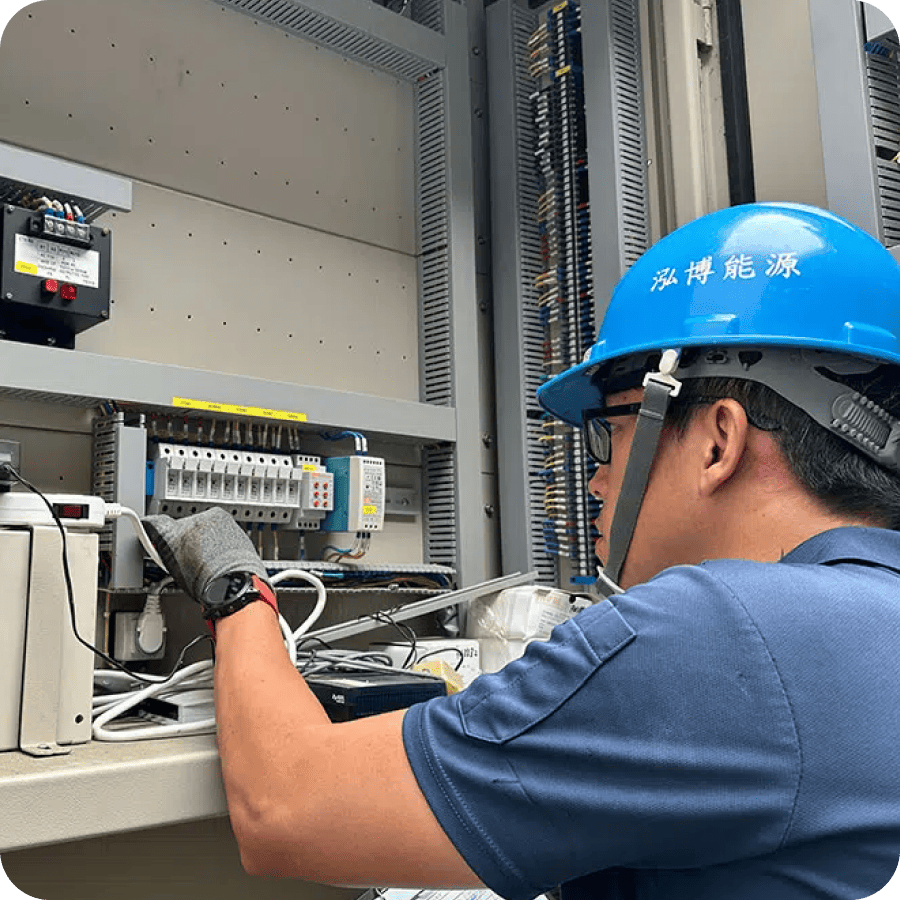

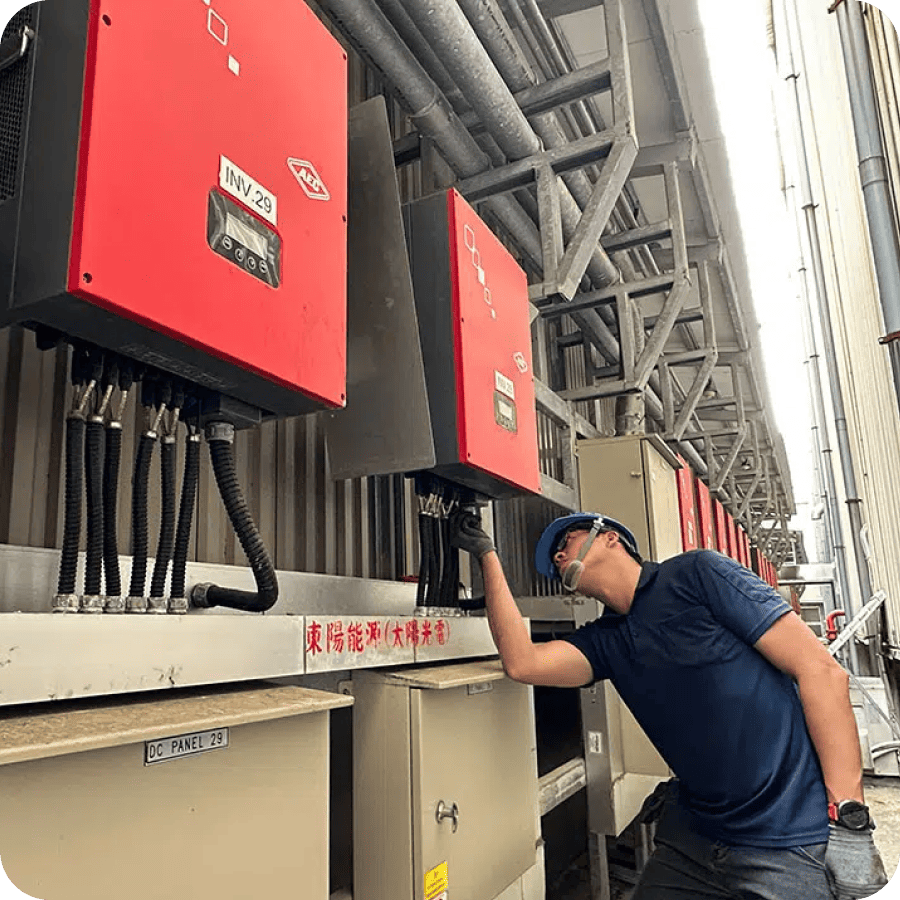

Troubleshooting and Repair

To minimize generation loss, revenue impact, and system downtime caused by equipment failures, timely troubleshooting and anomaly handling are performed to improve equipment availability and overall operational efficiency.

Power Plant Optimization

Intelligent Monitoring-Real time insights with proactive alerts

- Comprehensive monitoring of power output, solar irradiance, and PR indicators

- Automatic alerts for abnormal values to ensure rapid response

- Integrated weather forecasting to optimize generation prediction and operational planning

- Visual dashboards displaying key performance indicators for informed decision making

- Data driven recommendations based on historical performance

Predictive Analytics-Trend forecasting and operational strategy optimization

- Intelligent scheduling to optimize maintenance planning and improve workforce efficiency

- Dynamic resource allocation based on real time demand

- Predictive maintenance driven by data analysis to prevent failures

- Remote plant control enabling precise load reduction operations

- Cloud based knowledge platform with AI powered information retrieval

Flexible Dispatch and Collaboration-Rapid response with seamless coordination

- Cross platform support covering Android and iOS systems

- Real time notifications for swift issue awareness and resolution

- Intelligent task assignment to deploy the most suitable technicians

- Instant communication ensuring coordination between field teams and control centers

- Progress tracking for real time visibility into work order status and execution efficiency